INDUSTRIAL SPRING COATINGS AND SURFACE FINISHES

COATINGS THAT REDUCE NOISE, IMPROVE CORROSION RESISTANCE, DURABILITY AND PERFORMANCE OF SPRINGS AND WIREFORMS

A variety of coatings and surface finishes are available for the springs we produce. These treatments increase the durability and longevity of the springs we make, especially in unforgiving settings. If you are unsure which coating could help you, we can recommend the right treatment for you.

The following are examples of some of the coatings and finishes available on springs and wire forms from Spring Dynamics.

Phosphate & Soap

Phosphate and soap are inexpensive noise reducer and rust preventative often used on springs and wireforms. What makes phosphates effective is they chemically change the surface of a metal so it does not rust, chip, or scratch. The chemically altered surface protects the underlying base metal from corrosion and wear. Soap is similar. Specially formulated soaps act as microfilm rust inhibitors to protect aluminum, brass, copper, and carbon steel from developing brown and surface rust. Once soaped, the surfaces can then be painted, plated, or coated if need be.

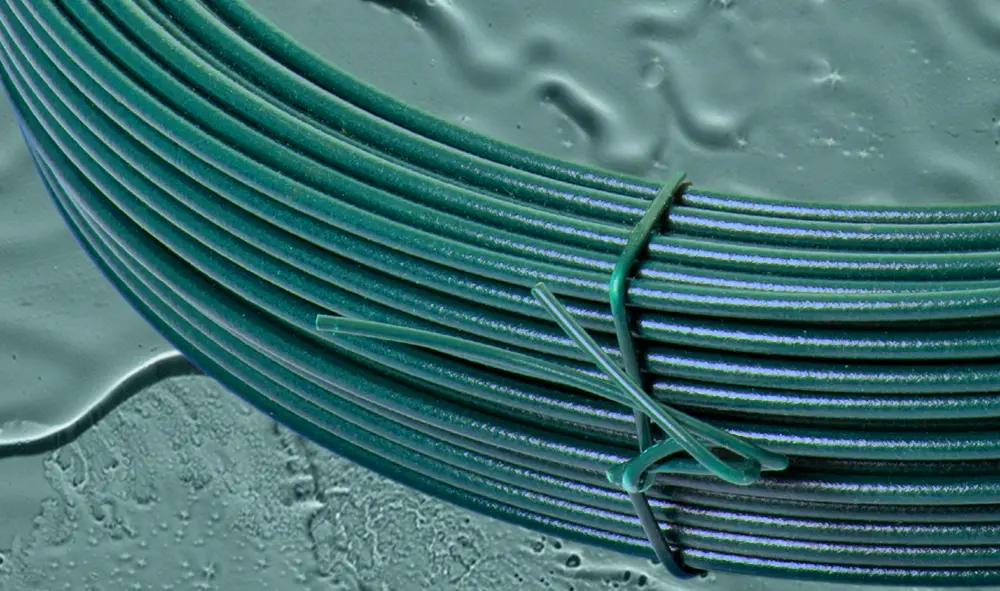

Teflon PTFE

Teflon is a polytetrafluoroethylene (PTFE) fluoropolymer. Teflon coatings can be used on carbon steel, aluminum, stainless steel, steel alloys, brass, and magnesium, as well as non-metallic materials. Many of us know Teflon as the nonstick coating used on pots and pans. Teflon coating on springs provides superior corrosion resistance, as well as noise reduction.

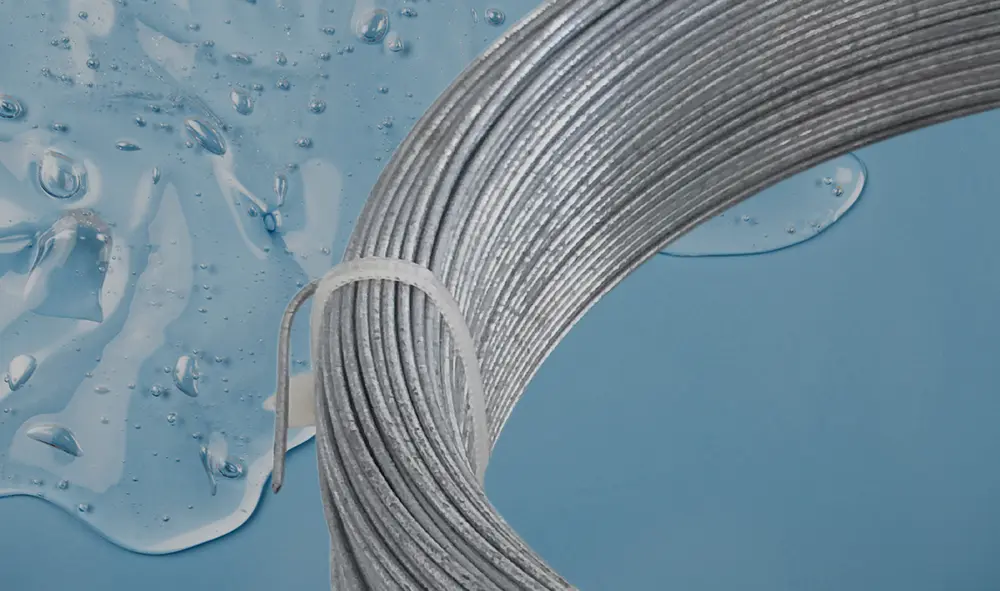

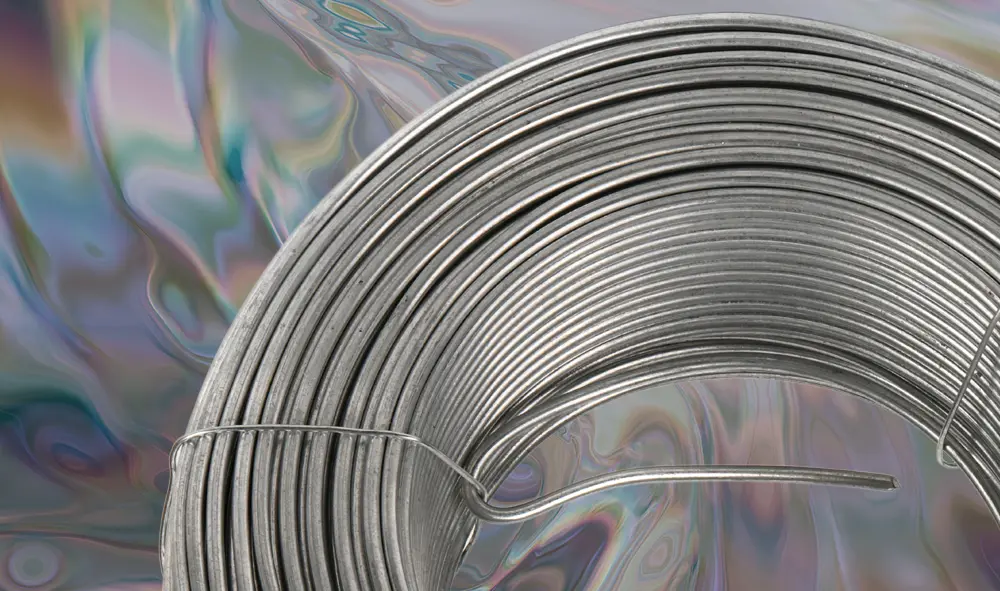

Zinc

Because zinc corrodes 30 times slower than iron, galvanizing metal with zinc is an effective way to protect metal against moisture. Zinc acts as a barrier between the base metal and the environment. Zinc is a sacrificial anode. Sacrificial Anodes are highly active metals that prevent a less active material, in this case the underlying material a spring is made of, from corroding. The added value of zinc is, even if a zinc coating is scratched, the underlying steel is still protected due to the chemical nature of the zinc coating.

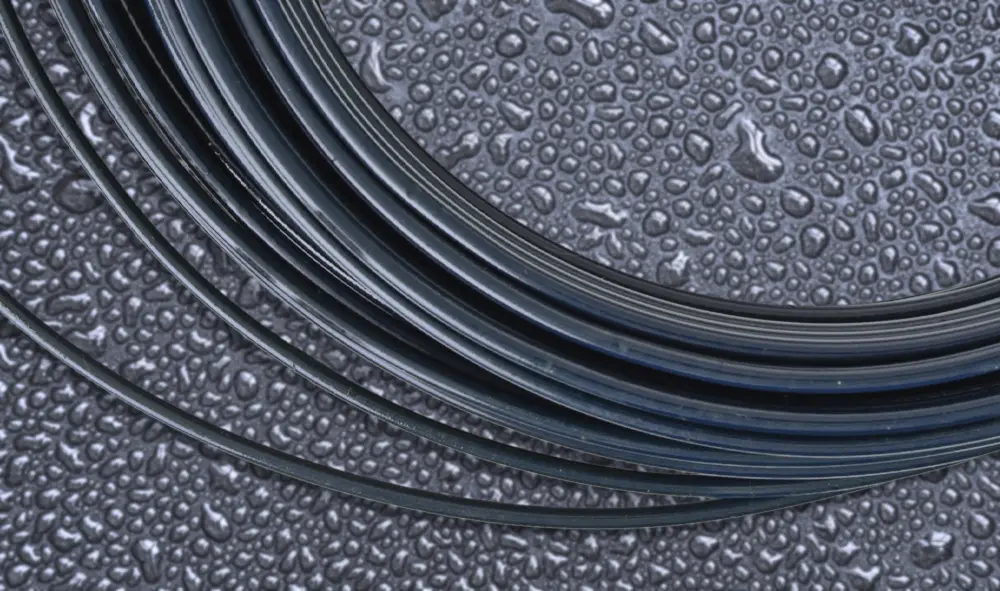

Plastisol Dip

Plastisol is the trade name for a rubber-like coating. At room temperature, Plastisol is liquid. When heated or cured, it turns to a flexible, rubber-like barrier. Plastisol bonds well to almost any metal and provides decades, if not a lifetime, of protection. Many of us have experienced Plastisol on garden tools and hand tools we use everyday at home.

Why Choose Spring Dynamics?

Spring Dynamics is an industry-leading, woman-owned manufacturer of springs for the automotive, agricultural, construction, appliance, aerospace, and military industries. We’re defined by our consistent attention to quality, education, and technology, and we’re committed to being a leader in the spring and wire forming industry.

Speed

We’ve achieved 100% on-time delivery each and every year since 2009.

Quality

We currently have achieved a YTD PPM of < 1.

Experience

We have 30+ combined years of making springs and wireforms.

Let Spring Dynamics Help You

Contact one of our spring experts at (810) 798-2622 or Request a Quote today.

Let's Discuss Your Spring Project