EXTENSION SPRINGS & COMPRESSION SPRINGS

Custom EXTENSION SPRINGS & COMPRESSION SPRINGS

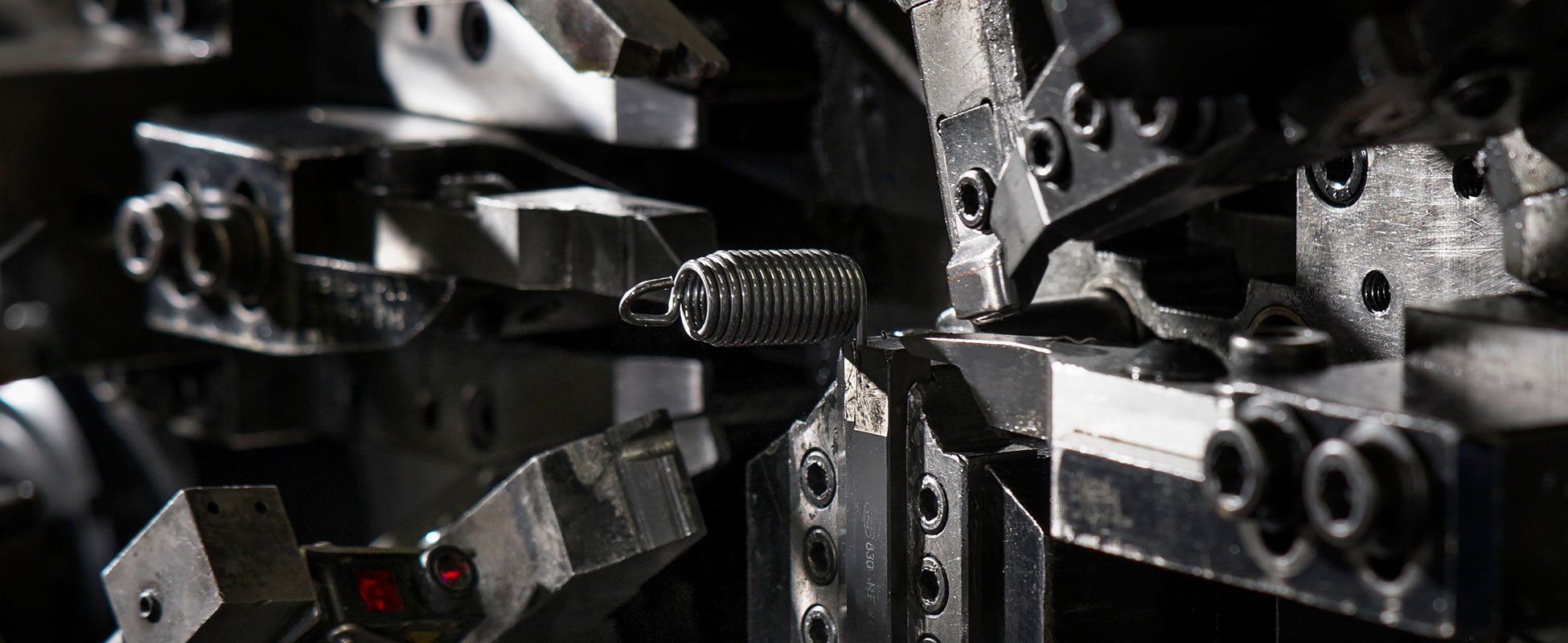

Spring Dynamics manufactures extension and compression springs for a variety of industries and applications. Each spring design is engineered to function in whatever assembly our customer needs. In order to ensure the whole assembly works in harmony, Spring Dynamics works to understand the end-use for each spring and incorporate that knowledge into the customer’s design.

Our extension springs are manufactured using the latest in CNC machinery and we have the capability to produce springs of all sizes and with a wide variety of loops or enclosures at each end.

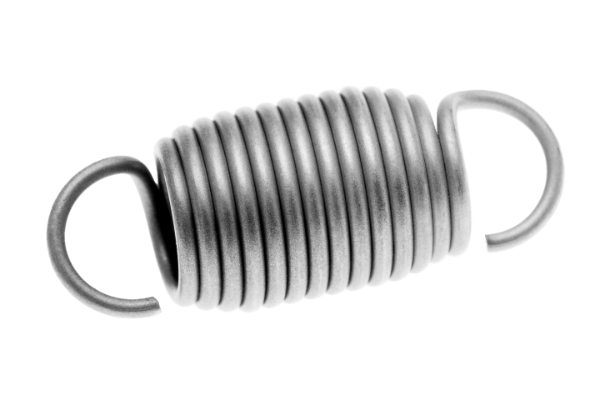

Extension Springs

Extensions springs supply a pulling force. These springs are made from various grades and alloys of round spring steel material. There are various hook configurations that can be applied to extensions springs including; Machine hooks, German hooks (arbor cut or extended tabs), English or cross center hooks (as shown below), and side or edge hooks.

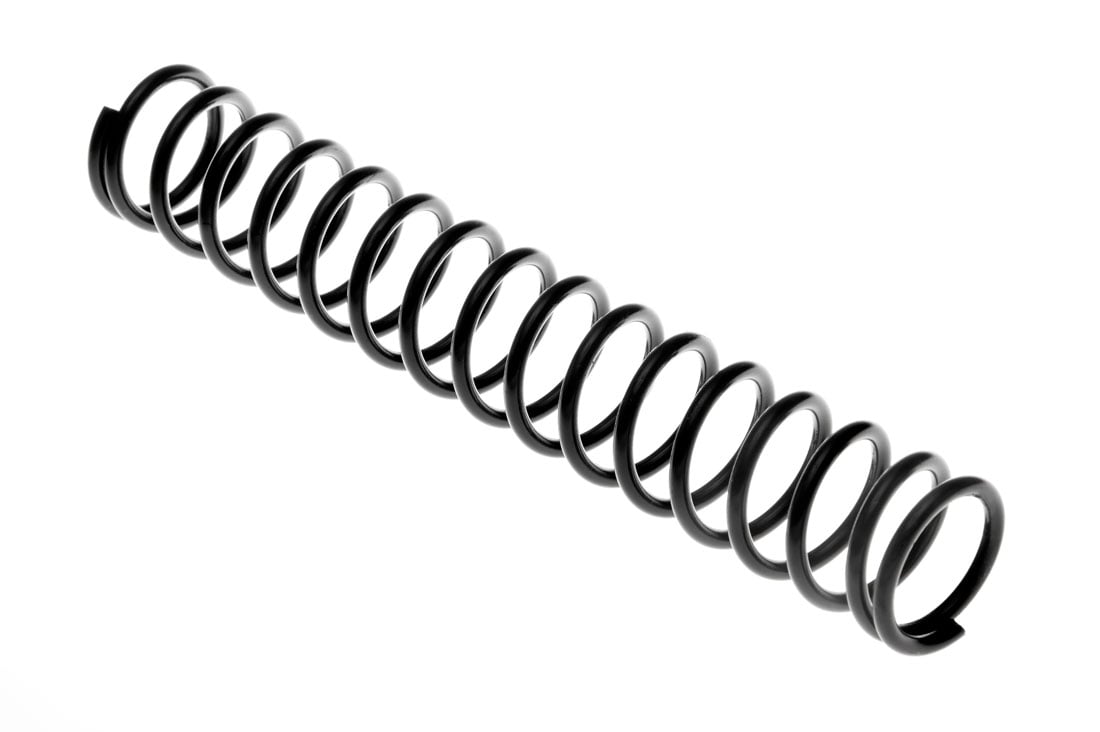

Compression Springs

Compression springs supply a pushing force. The helical bodies of these springs can be either left or right-hand wound and are generally cylindrical in shape. In addition to cylindrical bodies, other shapes such as tapered, barrel, and hourglass are also possible. These springs are generally made from round spring steel, but can also be made from square or rectangular spring steel for higher efficiency designs. There are several different end configurations that can be applied to compression springs as shown below.

Types of Compression Springs

Open Ends Compression Springs

With open ends, the coil pitch is the same throughout the body and end coils of the spring. In a compression spring with open, ground ends, the end coils are ground flat, perpendicular to the body’s axis.

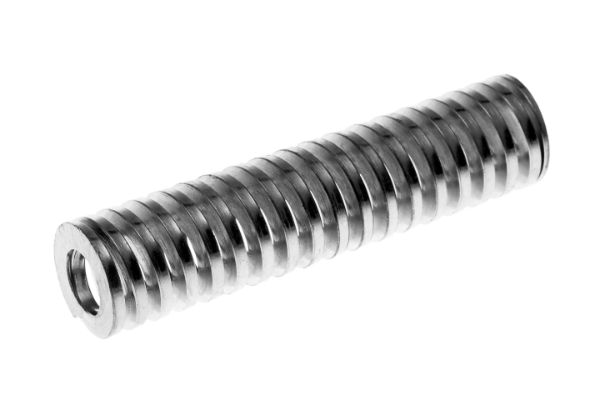

Closed Ends Compression Springs

For a compression spring with closed, unground ends, the coil pitch is reduced to zero at each end. For compression springs that have closed, ground ends, the coil’s pitch is reduced to zero at each end, and the ends are ground flat perpendicular to the body’s axis.

Case Study: Cutting cost with a better compression spring design

Problem:

Pedal assemblies require astronomical cycle life studies. Not only do these tests take a long time, but they have to be repeated every year, adding sometimes unnecessary costs to the manufacture of these mechanisms. Everyone is always looking for a way to cut costs, but how?

Solution:

Through experience and innovation, Spring Dynamics is always finding ways to build a better mousetrap. In this particular case, our team of engineers stumbled across an ingenious way to reduce the need to undergo the tedious testing required. They developed a compression spring that would meet the needs of the mechanism but was under so little stress that the cycle life was near infinite. After proving out their idea along with the customer, the requirement to cycle test the parts year after year was eliminated.

Results:

As mentioned before, testing can be costly. Not only is there highly specialized labor being exhausted, but there’s also the time that is taken from the testing equipment, the paperwork associated, and the repeated evaluation process necessary by manufacturer and user. By eliminating the need to test over and over again, we successfully eliminated all of the costs associated as well.

Case Study: Re-designed extension spring improves efficiency

Problem:

A customer was building an assembly that used a pretty basic extension spring. A problem occurred, however, when the line worker would try to pull a piece from its package to use. The hooks on the spring were making them grab on to each other, just like a Barrel-Of-Monkeys! This was unacceptable. The extra time it took the worker to separate parts, and the inherent damage that the tangling caused, were far too costly for the customer to absorb.

Solution:

The spring had been designed to work flawlessly, but without the forethought of assembly. Spring Dynamics’ engineers looked at the process, saw how the part was being assembled for themselves and sprung into action. They re-designed the end hooks of the part to be a completely closed-loop, eliminating the possibility of tangling in the box!

Results:

With the new design implemented, the customer quality group was satisfied. The tangling had been eliminated and at a minuscule cost impact. The part ran only slightly slower than it had before, and the added raw material needed to make the part was so minuscule that the piece price didn’t even have to increase.

Custom Extension Springs & Compression Springs