COUNTERBALANCE SPRINGS

Custom Counterbalance Spring

Spring Dynamics, Inc. specializes in counterbalance springs (aka: clock springs, power springs, spiral torsion springs, or flat springs). We are one of the very few spring manufacturers that offer counterbalance production.

Custom counterbalance springs to fit your needs

Spring Dynamics, Inc. specializes in counterbalance springs (aka: clock springs, power springs, spiral torsion springs, or flat springs). We are one of the very few spring manufacturers that offer counterbalance production.

Counterbalance or constant force springs offer several advantages compared with other types of springs:

- High force output in relatively small space requirements

- Provide linear torque through at least the first 360-degree revolution

- Longevity

Spring Dynamics specializes in making custom counterbalance springs to customer specifications. With our engineering and manufacturing aptitude, custom springs can be produced at almost the same time as stock springs.

If you are unfamiliar with counterbalance springs, your product development team is welcome to work with our engineering group to identify whether a counterbalance spring will function and package for your application – in many cases providing advantages not previously considered.

The complex, versatile geometries required for counterbalance springs are produced in line with proprietary machinery made in-house.

Using our own machinery is up to 20% faster than conventional machinery. These machines enable us to offer our customers unsurpassed quality at highly competitive prices.

About Counterbalance Springs

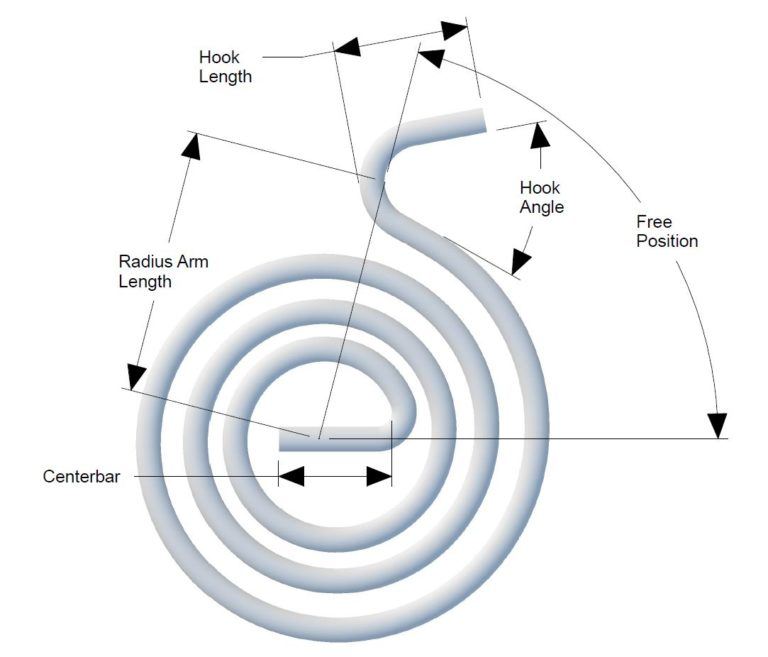

Counterbalance Springs springs are also used to apply rotational torque, but in a different design configuration than torsion spring. Counterbalance springs are made in a spiral shape to fit over a specified center mandrel. These springs apply torque through a moment arm in a spiral direction around the center mandrel. These springs are typically made from rectangular high carbon steel with a rounded edge.

Case Study: Creating a custom counterbalance spring

Problem:

Counterbalance springs are typically made, in recent history, in a one-step in-line process. Certain requirements cause manufacturers to add in a secondary operation to achieve a variety of customer-required geometries. In one particular case, a customer required the hook of the spring to be ‘closed’, or made into a loop rather than a hook. When our customer came to us with this design, and the inherent debilitating cost, we knew we had our work cut out for us.

Solution:

Spring Dynamics uses a proprietary process to manufacture counterbalance springs. Due to the versatility of our machinery, we were able to develop a mechanized attachment to the machine that would handle closing the hook while still in line, eliminating the extra cost of adding an entire secondary process to provide a finished product.

Results:

The solution that we provided worked very well. It worked so well, in fact, that the customer continued to use that design element in other programs. The innovation cut out over 10% of the cost of the original design and is still in use today.

Custom Counterbalance Springs